The Bagpipe Society

Tools of the Trade: Goodacre's Razor - A Cut Below the Others

Julian shares the secret of his favourite tuning tool: What is the wisest course of action if you find that there is one note on your chanter which sounds a wee bit flat? One approach to any problem in life is to ignore it and hope it just goes away. With bagpipes this can lead you into the bad habit of trying to raise the note by squeezing a bit harder which can cause other tuning problems. There are several other ways of dealing with this problem. The wisest initial approach is probably to consult your Venerable Pipemaker, even though it might involve money passing hands. The flat note might be a result of the chanter bore contracting in which case he can re-ream it. Or it could be a peculiarity that your reed has developed, in which case a replacement reed might solve the problem.

If you are confident in the bore and the reed there are still other ways of raising the pitch of an individual note. Ideally the hole needs to be repositioned, either slightly higher on the chanter to create a shorter column of vibrating air, which raises the pitch of the note, or lower down to lengthen the column if the note sounds sharp. But this alters the outward appearance of the chanter and is a fairly drastic option that should only be considered in the very last resort. Makers have to do this many, many, times when initially developing, or making improvements to, a design of any type of woodwind instrument in order to arrive at the optimum positions for all the finger holes. Again, this is a job best left to your pipemaker.

However there are two less radical ways which achieve the effect of shortening the column of vibrating air, thus raising the pitch of a single note, achievable by any keen ‘hands on’ piper. One is to increase the diameter of the finger hole. The other technique is to undercut the hole. This involves removing a small piece of wood on the inside of the upper side of the finger hole. (A on Fig 1). It does not affect the outward appearance of the chanter, it is reversible, and I have designed a nifty little tool for this very purpose.

Undercutting appears simple, but in practice there remains the problem of swiftly, accurately and neatly removing a small piece of wood at the bottom of the finger hole without damaging its outside appearance. It is especially tricky on my narrow bored Leicestershire smallpipe chanter which has very small finger holes that leave little room to manoeuvre. I experimented with various knives for carving and also tried files and a Dremel drill, but all were hard to use, inefficient and could easily scuff or damage the visible outside of the fingerhole. Eventually I developed a simple cutting knife shaped somewhat like a crochet hook, which is easy to use, since you put it into the finger hole and pull it towards you at an angle. You can then accurately control how much wood to remove without damaging the surface diameter of the finger hole. I find it an invaluable tool and for reasons that I explain later I have immodestly named it ‘Goodacre’s Razor’.

I make these from roll pins, which are fixing devices used in light machinery to secure metal collars and pulleys onto shafts and they operate in a similar way as a nail does in wood. They are made from spring steel which is rolled into a tube with the seam left open which allows it some springiness so that it will stay securely in position when it is driven into a slightly undersize hole. They are available in a variety of diameters and I recommend buying the longest ones available. I bought some recently on the ALL-TOOLS-DIY Ebay shop. (Beware! There are also similar roll pins made like little Swiss rolls- these are useless for making a Goodacre’s Razor).

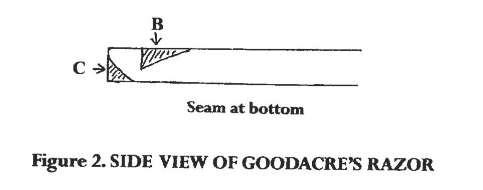

Even though they are made from hard spring steel it is still possible to file them with fine needle files. To start with you need to remove a triangle (B on Fig 2). when viewed from the side. Then round off some f the back heel (C on Fig 2). You should end up with something that resembles a tubular crochet hook. Now you can get a fine round needle file through the end and file the edge (Fig 2). from inside, so that the bevel of the knife edge is on the inside. Fine honing can be done with a small rolled- up screw of the finest wet and dry paper; mine hardly ever need re- sharpening.

Finally a handle is needed. You could just hold one in a pin vice, but it is more satisfactory to turn a nifty handle with the correct diameter hole in it, and epoxy the pin in place. Bingo! I made a series of these knives in different diameters, but in practice I nearly always use my 3/32 inch and 1/8 inch ones.

There is a historical reason why I named this tool Goodacre’s Razor. Since 1985 I have subscribed to FoMRHI- The Fellowship of Makers and Researchers of Historical Instruments. This admirable organization produces a journal as a forum for all instrument makers to publish and share their researches, tips, theories and anything relating to instrument making. Some of the articles published are very practical whereas others are analytical and theoretical. On a few occasions, debates between rival makers become tedious. About 25 years ago an increasingly heated exchange began between two string instrument makers about some aspect of their own esoteric obsessions. I forget the details; possibly they were clinging to their opposing opinions about the correct catlins for a Spanish vihuela. But I do recall it was the sort of subject liable to make any woodwind instrument maker yawn. The journal is published as a quarterly and it became increasingly frustrating to wait another 4 months to be faced with a further chapter of their disagreements which were of very little interest to most of the members; especially those who, like me, are more drawn to the nuts & bolts & glue type of articles.

At some stage one of these sparring makers introduced Occam’s Razor to support his personal argument. I had never heard of it, but apparently Occam was a 13th century philosopher who may, or may not, have stated that if there are two solutions to a problem the simplest is correct. This stirred up more hot air articles about the validity of Occam and his wretched Razor. I was fed up with all this theoretical clap trap filling up the journal and I cheekily wrote two articles.

One was a tongue-in-cheek inquiry asking where I could buy an Occam’s razor for scraping bagpipe reeds. The other article was my description of this undercutting tool and how to make it, which I ended by stating ‘Make some for yourself and think of Goodacre when you use yours. Without one I could not be held responsible for the temper of myself or my chanters’.

I am not advocating that every piper rushes out and makes a Goodacre’s Razor. Undercutting is a fairly radical process and this tool is really for an instrument maker or someone who enjoys gaining experience in tuning instruments. It is always best to think long and hard before removing any wood from your valuable chanter even though it is possible to reverse the effects of the process by building up the undercut area again with wax or filler.

Hopefully all your chanters are in tune and sounding sweet and you never have need of a Goodacre’s Razor!

- Data Processing Notice (GDPR)

-

@BagpipeSociety on X (formally known as Twitter)

-

TheBagpipeSociety on Instagram

-

BagpipeSociety on Facebook

BagpipeSociety on Facebook

Something wrong or missing from this page? Let us know!